Altin Kural Metal company as a reliable companion beside his customers, provides solutions for customers needs.

We offer different machine types according to customer demands.

Models:

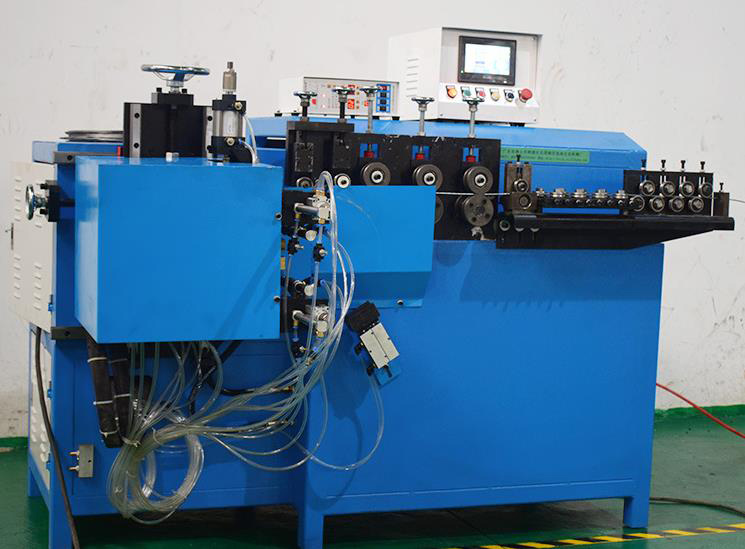

Ring making machine

Servo motor:1.5KW,

Reduction gear:1:5

Wire feed speed: 35meters/min,

Production speed:20pcs /min,( 80mm diameter as example,the bigger diameter the slower speed),

Ring diameter:50mm-250mm,

Ring wire diameter:2mm-5mm (low carbon steel, perimeter tolerance: +_0.25)

Ring diameter tolerance:0.5mm

Flat degree:<0.5mm

Input voltage:380V

Welding power:40KVA

Load continuity:50%

Compressed air pressure:0.6MPa

Cooling water flow:50L/min

Dimension (L*W*H)(mm):1950*1450*1500

Weight:600KG

Tools:one set (commonly used)

Decoiler:It is normal without cost if customer want automatic decoiler we can provide but price have to charge 3000USD more.

Number of feeder rollers:can provide according to customers request.

And this machine is specially designed for produce this kind of rings.Other functions can be added if required.

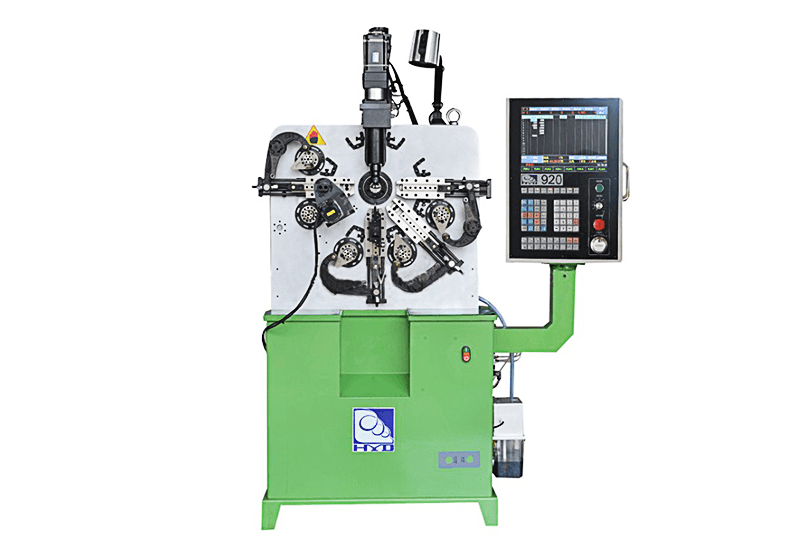

Helicoil spring machine

|

Model |

HYD-QC-16 |

|

Axis Count |

5 axis |

|

Wire size range |

M2-M16 |

|

Maximum wire length |

Unlimted |

|

Max feeding speed |

141m/min |

|

X-axis motor output |

2.7KW |

|

Y-axis motor output |

2.0KW |

|

Z-axis motor output |

1.0KW |

|

B-axis motor output |

1.0KW |

|

A-axis motor output |

0.2KW |

|

C-axis motor output |

0.4KW |

|

Dimension(L×W×H) |

600×1300×1800mm |

|

Weight |

600kg |

|

Power AC |

3-380VAC50Hz |

Outside Chamfering machine

JN 160 Spring Chamfering Machine

Functions And Applications

This machine is mainly used for the chamfering of the cylindrical springs.

|

Model |

Chamfering Scope |

Specifications Of The Grinding Wheel |

Rotation Rate Of The Main Axle |

Rotation Rate Of The Conveyer Belt |

Total Power |

External Dimension |

|

JN160 |

Outer Diameter 15-45mm Height 18-65mm |

Φ160×200×Φ32 (mm) |

2500r/min |

3.2r/min |

3kw |

L1.3×W1.6×H0.9 (m) |

CNC Spring Setting Processor

This machine uses PID control which guarantees the high efficiency and easy operation, mainly used for the setting of cylindrical springs.

This machine is composed of the main engine and the control panel. According to the production requirements, the pressing devices can be set to single or multiple drive mode by using the man-machine interface of the control panel. After feeding, the feeding plate will turn automatically for the spring setting, the machine will be shut down automatically when reaching the preset quantity requirements.

Technical Parameters

|

Models |

Outer Diameter Of The Spring |

Free Height Of The Spring |

Maxi Pressure |

Number Of Pressing |

Productivity |

Air Pressure |

|

JNLD-1 |

Φ5-10mm |

10-25mm |

1000N |

1-3 |

≥2800pcs/8h |

0.5-0.75Mpa |

|

JNLD-2 |

Φ8-20mm |

15-35mm |

2000N |

1-3 |

≥2800 pcs/8h |

0.5-0.75Mpa |

|

JNLD-3 |

Φ12-25mm |

20-45mm |

3000N |

1-3 |

1800-2600 pcs/8h |

0.6-0.75Mpa |

|

JNLD-4 |

Φ20-35mm |

20-65mm |

4000N |

1-3 |

1800-2600 pcs/8h |

0.6-0.75Mpa |

|

JNLD-5 |

Φ20-45mm |

20-100 mm |

5000N |

1-3 |

1800-2600 pcs/8h |

0.6-0.75Mpa |

|

Remarks |

Manufacture according to the Customer needs. |

|||||

Inside Chamfering Machine

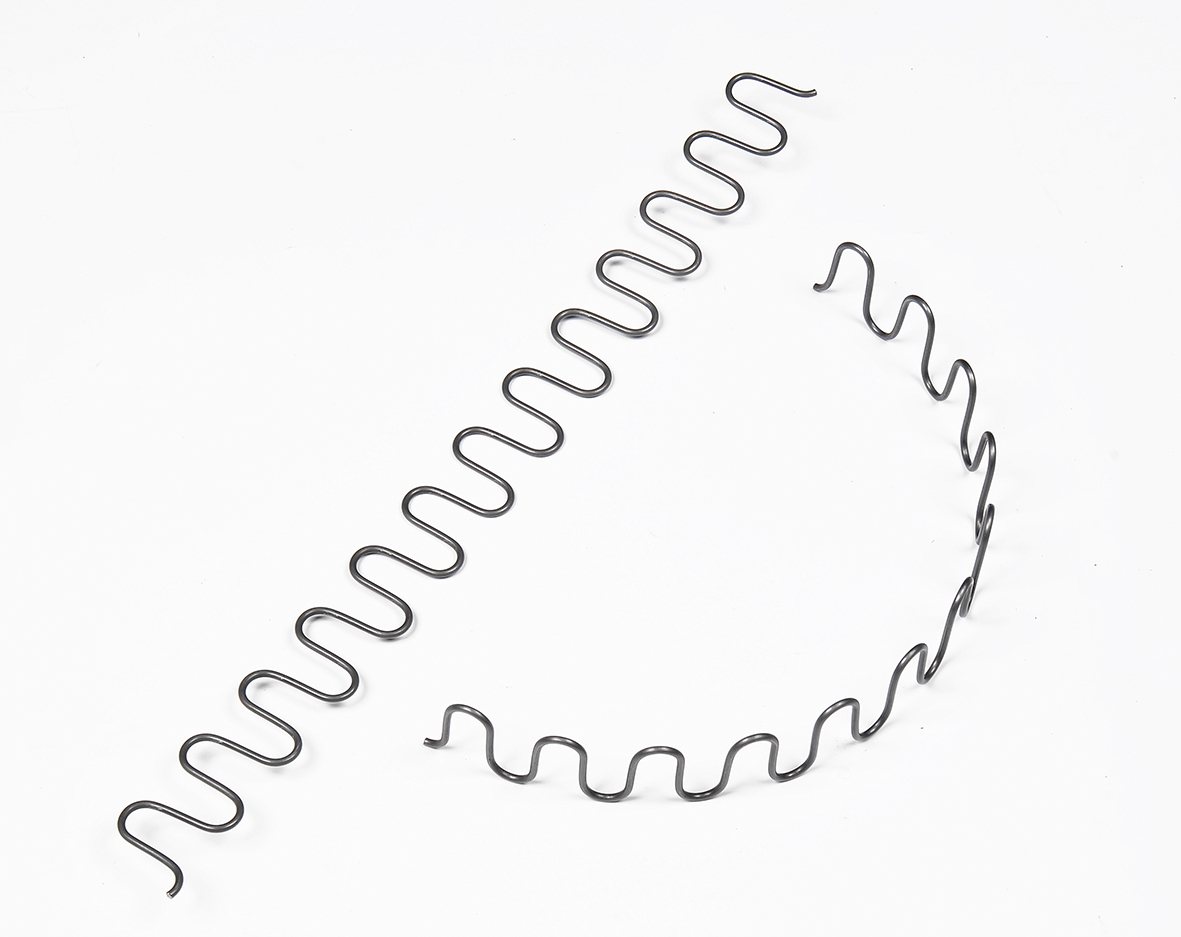

Zigzag Spring Machine

Product Description

Single servo motor control: Cam

Firmly structure

Simplicity of operation

Optional: Hydraulic cutter and spring collector

Specification

Wire diameter (mm) 2.5-5.0

Max. spring OD(mm) 20-80

Wave peak (mm): 28-50

Wave Width (mm) : 16-60

Max. spring length (mm) 20-80

Production speed (U/min) 100

Motor power: 2.2Kw

Machine weight (kgs) 380